Airbus is an aircraft manufacturing subsidiary of EADS, an European Aerospace Defence and Space Company.

Airbus A300

The Airbus A300 is a short to medium range widebody aircraft. Launched in 1972 as world's first product of the Airbus consortium of European aerospace companies, wholly owned today by EADS. The A300 ceased production in July 2007, along with the smaller A310.

The mission requirements were given in 1966 by Frank Kolk, an American Airlines executive, for Boeing 727 replacement on busy short to medium range routes such as US transcontinental flights. His brief included a passenger capacity of 250 to 300 seated in a twin-aisle configuration and fitted with two engines, with the capability of carrying full passengers without penalty from high altitude airports like Denver. American manufacturers responded with widebody trijets, the McDonnell Douglas DC-10 and the Lockheed L-1011 Tristar, as twinjets were banned from many routes by the FAA. French president Charles de Gaulle resented the US domination of civil aviation and wanted a European airliner that could compete with American designs. Concorde was part of the answer, designed for intercontinental routes; the other was the A300, designed to meet Kolk's US domestic requirements.

In September 1967, the British, French, and German governments signed a Memorandum of understanding (MoU) to start development of the 300-seat Airbus A300. An earlier announcement had been made in July 1967, but at that time the announcement had been clouded by the British Government's support for the Airbus, which coincided with its refusal to back British Aircraft Corporation (BAC) proposed competitor, a development of the BAC 1-11, despite a preference for the latter expressed by British European Airways (BEA).

Another problem was the requirement for a new engine to be developed by Rolls Royce, the RB207. In December 1968, the French and British partner companies (Sud Aviation and Hawker Siddeley) proposed a revised configuration, the 250-seat Airbus A250. Renamed the A300B, the aircraft would not require new engines, reducing development costs. To attract potential US customers, American General Electric CF6-50 engines powered the A300 instead of British RB207. The British government was upset and withdrew from the venture; however, the British from Hawker-Siddeley stayed on as a contractor, developing the wings for the A300, which were pivotal in later version's impressive performance from short domestic to long intercontinental flights.

In 1972 the A300 made its maiden flight. The first production model, the A300B2, entered in service in 1974. The A300 was the first airliner to use just in time manufacturing techniques. Complete aircraft sections were manufactured by consortium partners all over Europe. These were airlifted to the final assembly line at Toulouse-Blagnac by a fleet of Boeing 377-derived Aero Spacelines Super Guppy aircraft.

Informations obtained : James Gibb's Civil Aircraft

Images obtained : Google Images & Flightglobal.com

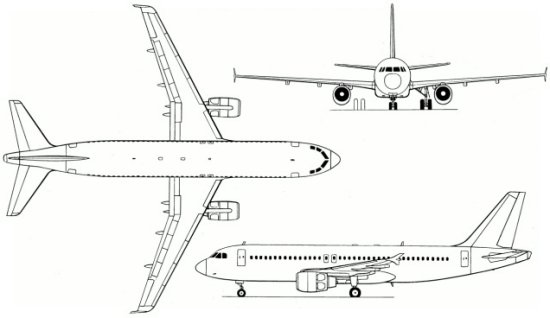

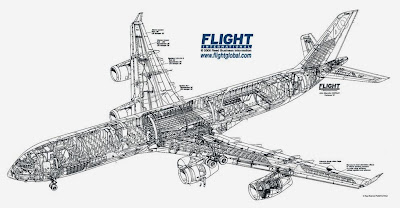

AIRBUS A320

The Airbus A320 faily of short to medium range commercial passenger airliners manufactured by Airbus, Family members include the A318, A319, A320, and A321, as well as the ACJ business jet.

First delivered in 1988, the A320 pioneered the use of digital fly-by-wire flight control system in a commercial aircraft. With more than 3,000 aircraft of the A320 family built, it is the second best selling jet airliner family of all time after the family's primary competition, the Boeing 737.

After the initial success of the A300, Airbus began developing a new model aimed at replacing the world's most popular aircraft at the time, the Boeing 727. The new Airbus would be of the same size, yet offer improved operating economics and various passenger capacities. The digital technology in the A320 would herald a two generation technology leap over the all analogue Boeing 727 and be a generation ahead of the Boeing 737-300/-400/-500 series. The A320 was targeted at the global fleet replacement requirements for the 727 and early variants of the 737.

After the oil price rises in 1970s, Airbus needed to minimise the trip fuel costs of the A320. To that end, Airbus incorporated advanced features including fly-by-wire flight control, composite primary structures, centre of gravity control using fuel, glass cockpit (EFIS) and a two-person flight deck. The end result was the A320 consumes 50% less fuel than the 727.

Bernard Ziegler was the initiator of the aircraft's then revolutionary fly-by-wire flights controls with sidestick cockpit controller and full glass cockpit. He successfully convinced aviation authorities of the concepts validity.

Components from various Airbus plants are transported to the final assembly plant at Hamburg Finkenwerder for the A318/ A319/ A320/ A321 and to Toulouse Blagnac for the A320. Nearly all assemblies are moved using Airbus A300-600ST 'Beluga' outsized transporters. The Airbus A320s sold to China to be delivered between 2009 and 2012 will be assembled in the People's Republic of China in Tianjin. The A320 family has the highest production rate ever for any commercial airliner. In response to continuing strong demand, Airbus continues its steady production ramp-up programme from 30 aircraft per month reached at the end of 2006, to 32 in mid of 2009, and 40 by end of 2009.

The A320 features a computerised on board maintenance system. With the exeption of the very earliest A320s, most can be upgraded to the latest avionics standards, keeping the aircraft advanced even after two decades in service.

The flight deck is equipped with EFIS with sidestick controllers. At the time of the aircraft's introduction, the behaviour of the fly-by-wire system (equipped with full flight envelope protection) was a new experience for many pilots.

Two suppliers provide turbofan engines for the A320 series: CFM International with their CFM56, and International Aero Engines, offering the V2500.

Informations Obtained : James Gibb's Civil Aircraft

Images Obtained : Google Images & Flightglobal.com

Airbus A330

The Airbus A330 is a large capacity, wide body, medium to long range commercial passenger airliner. It was developed at the same time as the four engined Airbus A340.

The A330's fuselage and wings are virtually identical to those of the smaller A340 variants, although it has a different engines. The A330 basic fuselage design is inherited from the A300, as is the nose/cockpit section and the fly-by-wire system and flight deck from the A320. Both the A330 and A340 are assembled on the same final assembly line at Toulouse-Blagnac, France.

By the end of March 2008, a total of 921 A330's had been ordered and 533 delivered.

There are two main variants of the A330. The A330-300 was launched in 1987 with introduction into service in 1993. The A300-200 was launched in 1995, introduced in 1998 and comes in passenger, freighter and tanker versions.

The A330-200 was developed to compete with the Boeing 767-300ER. The A330-200 is similar to the A340-200 or a shortened version of A330-300. With poor sales of the A340-200 (of which only 28 were built), Airbus decided to use the fuselage of the A340-200 with the wings and engines of the A330-300. This significantly improved the economics of the plane and made the model more popular than the four engined variant.

Its vertical fin is taller than that of the A330-300 to restore its effectiveness due to the shorter moment arm of the shorter fuselage. It has additional fuel capacity and, like the A330-300, has a Maximum Take Off Weight (MTOW) of 233 tonnes. Typical range with 253 passengers in a three class configuration is 12,500 km (6,750 nautical miles).

Power is provided by two General Electric CF6-80E, Pratt & Whitney PW4000 or Rolls Royce Trent 700 engines. All engines are ETOPS-180 min rated. First customer deliveries, to ILFC/Canada 3000, were in April 1998.

The A330-200 has sold strongly since its launch, outselling the Beoing 767-300ER by 23 to 9 in 2004. As a result, Boeing has asked both Rolls Royce and GE to design engines that enable 787 Dreamliner to be more 15% economical than A330-200.

Due to flagging A300-600F and A310F sales, Airbus first began marketing a freighter derivative of the A330-200 around 2000-2001, although it was not launched at this time. The A330-200F re-emerged at the 2006 Farnborough Air Show and received its industrial go ahead in January 2007. Entry into service is planned for the second half of 2009.

The A330-200F is a mid-size, long haul all-cargo aircraft capable of carrying 64 tonnes over 4,000 NM / 7,400 km, or 69 tonnes up to 3,200 NM / 5,930 km. It introduces a new versatile main-deck cargo loading system that will be able to accommodate both pallets and containers. Several different arrangements will be possible on the main deck, taking up to 23 Side by Side (SBS) pallets, aimed at the high volume, high value commodities or Single Row (SR) loading of 16 pallets (96"x96"x125" SR pallets) and/or nine AMA containers aimed at the general cargo higher density markets.

Informations Obtained : James Gibb's Civil Aircraft

Image Obtained : Google Image & Airplane-Pictures.net

Airbus A340

The Airbus A340 seats between 261 and 380 passengers, and has a range between 6,700 and 9,000 NM. It is similar in design to the twin engined A330.

The first published studies for the A340 were as the TA11 in 1981, as shown in the November issue of Air International Magazine (coinciding with the display of the A300 at that years's Franborough Air Show). Concept drawings of the A320 (SA 9) and and A330 (TA 9) were also published, along with estimated performance figures by Airbus Industry

The A340 was launched in June 1987 as a long range complement to the short range A320 and the medium range A300. At the time, Airbus's twinjet's were at a disadvantage against aircraft such as Boeing 747 because of the ETOPS problem as defined by the current regulations: two engined aircraft had to stay within 60 minutes' of flying distance of a suitable diversion airport, which prevented them from competing on long overwater routes. Furthermore, the existing ETOPS immune widebodies in the 250-300 seat range, the trijet DC-10 and L-1011, were aging, as they had been in service since the early 1970's. The A340 was designed in parallel with the twin engined A330: both aircraft share the same wing and similar fuselage structure, and borrow heavily from the advanced avionics and composite structure technology developed for the A320.

Both the A330 and A340 are assembled on the same final assembly line at Toulouse-Blegnac, france. The four engined A340is able to fly long over water routes. Because of its ETOPS-immunity, Virgin Atlantic Airways used the motto "4 Engines 4 Long Haul," on its A340 fleet.

The A340 was originally intended to use the new superfan engines of IAE (International Aero Engines) in the A340 but IAE decided to stop their development. The engines nacelles of the superfan engine consisted of provisions to allow a large fan near the rear of the engine. As a result of the superfan cancellation by IAE, the CFMI CFM-5C4 was used as the sole engine choice instead of being an alternate choice as originally envisioned. The longer range versions, the A340-500 and 600, are powered by Rolls Royce Trent 500 engines.

When the A340 first flew in 1991, engineers noticed that the wings were not strong enough to carry the outboard engines at cruising speed without warping and fluttering. To alleviate this, an underwing bulge called a plastron was developed to correct airflow problems around the engine pylons and to add stiffness. The modified A340 began commercial service in 1993 with Lufthansa and Air France.

The A340 incorporates high technology features such as fully digital fly-by-wire flight control system. It also uses a sidestick controller instead of normal control columns. There is one joystick to the left of the pilot and one to the right of the co-pilot. The A340's flight deck is highly similar to the A320's, and employs a common pilot rating with the A330. This enables A330/A340 flightcrews to fly A320 and vice-versa with minimal extra training. This saves costs for airliners that operates both aircraft families. The cockpit also features CRT-based glass cockpit displays on the A340-200 and A340-300 and LCD based on - 500 and -600. Some composite primary structures are also used.

Informations Obtained : James Gibb's Civil Aircraft

Image Obtained : Google Images & Flightglobal.com

Airbus A350

The Airbus A350 is a long range, mid sized, wide body family of airliners currently under development, designed to compete with Boeing 777 and Boeing 787. The A350 will be the first Airbus with fuselage and wing structures made primarily of carbon fiber reinforced plastic. It is scheduled to enter in service in 2013.

When Boeing announced its 787 Dreamliner project, it claimed the lower operating costs of this airplane would make it a serious threat to the Airbus A330. Publicly, Airbus initially rejected this claim, stating that the 787 was itself just a reaction to the A330, and that no response was needed to the 787.

The airlines pushed Airbus to provide a competitor, as Boeing had committed the 787 to have 20% lower fuel consumption than today's equivalent types. Initially Airbus proposed a simple derivative of A330, unofficially dubbed of the 'A330-200Lite', with improved aerodynamics and engines similar to those on the 787. The airlines were not satisfied and Airbus committed 4 billion to a new design to be called the A350. The original version of the A350 superficially resembled the A330 due to its common fuselage cross-section and assembly. A new wing, engines and a horizontal stabilizer were to be coupled with new composite materials and production methods applied to the fuselage to make the A350 an almost all-new aircraft.

On 6 October 2005 full industrial launch of the program was announced with an estimated development cost of around 3.5 billion. This version of the A350 was planned to be a 250-300 seat twin engined wide body aircraft derived from the design of the existing A330. Under this plan, the A350 would have modified wings and new engines while sharing the same fuselage cross section as its predecessor. Controversially, the fuselage was to consist primarily of Al-Li rather than the CFRP fuselage on the 787. It was to see entry into service in 2010 in two versions; the A350-800 capable of flying 8.800 nautical miles (16,300 km) with typical passenger capacity of 253 in 3-class configuration and the 300-seat (3-class) A350-900 with 7,500 nautical mile (13,890 km) range.

On September 2007, Airbus rolled out new design advances to a gathering of 100 representatives from existing and potential XWB customers. The A350 XWB will be built on the technologies developed for Airbus A380 and will have similar cockpit and fly-by-wire systems layout. Airbus claim that 52% of the aircraft will be made out of composites, 20% Al/Al-Li, 14% titanium, 7% steel, and 7% the balance. This compares to the Boeing 787, which consists of 50% composites, 20% aluminium, 15% titanium, 10% steel and 5% the balance. October 2008 is the Airbus internal goal to freeze the design and Airbus expects 10% lower airframe maintenance cost and 14% lower empty seat weight than competing aircraft.

Airbus claims that the new design provides a better cabin atmosphere with 16% humidity level during flight cruise and typical cabin altitude at or below 6,000 ft, pressurization at 6,000 ft (1,800 m) and flow management system that adapts cabin airflow to passenger load with draft-free air circulation.

Informations Obtained : James Gibb's Civil Aircraft

Image Obtained : Google Image, Flightglobal.com, & AviationExplorer.com

Airbus A380

The Airbus 380 is a double-deck, wide-body, four engine airliner manufactured by the European corporation Airbus, an EADS (European Aeronautic Defence and Space company) subsidiary. The largest passenger airliner in the world. The A380 made its maiden flight on 27th April 2005 from Toulouse, France, and made its first commercial flight on 25th October 2007 from Singapore to Sydney with Singapore Airlines. The aircraft was known as the Airbus A3XX during much of its development phase, but the nickname Superjumbo has since become associated with it.

The A380's upper deck extends along the entire length of the fuselage. This allows for a cabin with 50% more floor than the next-largest airliner, the Boeing 747-400, and provides seating for 525 people in standard three class configuration or up to 853 people in all economy class configuration. The A380 is offered in passenger and freighter versions. The A380-800, the passenger model, is the largest passenger airliner in the world, superseding the Boeing 747, but has a shorter fuselage than the Airbus A340-600 which is Airbus's next biggest passenger aeroplane. The A380-800F, the freighter model, is offered as one of the largest freighter aircraft, with a listed payload capacity exceeded only by Antonov AN-225. The A380-800 has a design range of 15,200 kilometres (8,200 nmi), sufficient to fly from New York to Hong Kong for example, and a cruising speed of Mach 0.85 (about 900 km/h or 560 mph at cruise altitude).

On 19 Dcember 2000, the supervisory board of newly restructured Airbus voted to launch a Euro 8.8 billion program to rebuild the A3XX, re-christened as the A380, with 55 orders from six launch customers. The A380 designation was a break from previous Airbus families, which had progressed sequentially from A300 to A340. It was chosen because the number 8 resembles the double-deck cross section, and is a lucky number in some Asian countries where the aircraft was being marketed. The aircraft's final configuration was frozen in early 2001, and manufacturing of the first A380 wing box component started on 23rd January 2002. The development cost of the A380 had grown to Euro 11 billion when the first aircraft was completed.

Boeing, meanwhile, restructed the 747X programme several times before finally launching the 747-8 Intercontinental in November 2005 (with entry into service planned 2009). Boeing chose to develop a derivative for the 400 to 500 seat market, instead of matching the A380's capacity.

Major structural sections of the A380 are built in France, Germany, Spain, and the United Kingdom. Due to their size, they are brought to the assembly hall in Toulouse in France by the surface transportation, rather than by the A300-600ST Beluga aircraft used for other Airbus models. Components of the A380 are provided by suppliers from around the world; SAFRAN, United Technologies, General Electric, and Goodrich.

Informations Obtained : James Gibb's Civil Aircraft

Image Obtained : Google Image, Airliners.net

Comments from krishna

ReplyDeleteIt is very informative though I traveled many times I really do not understand the differences. Good one pls keep on updating.

thank u mr murali, keep reading, i'll be writing more

ReplyDelete